The olfactory system of a human is fascinating. The olfactory mucous membrane perceives odor, and neurotransmitters carry the message to our brains. In the case of hydrogen sulfide (H2S), that foul, notorious, rotten egg odor tells corrosion engineers a great deal of critical information.

H2S is a colorless, poisonous, corrosive, and odorous gas produced commonly within wastewater collection networks and treatment facilities. At V&A, we have decades of experience investigating corrosion problems in the municipal wastewater industry. The smell of H2S is a big indicator to us that corrosion analysis and mitigation may be urgently needed at the source of the odor emissions, as well as upstream and downstream. The higher the H2S concentration within the sewers, pump stations, and treatment processes causing odorous ambient conditions nearby, the greater the likelihood of corrosion to utility infrastructure and the higher the safety risk to operations personnel. The risks associated with odor complaints will only become more costly to respond to if left alone or simply covered up.

How is hydrogen sulfide produced?

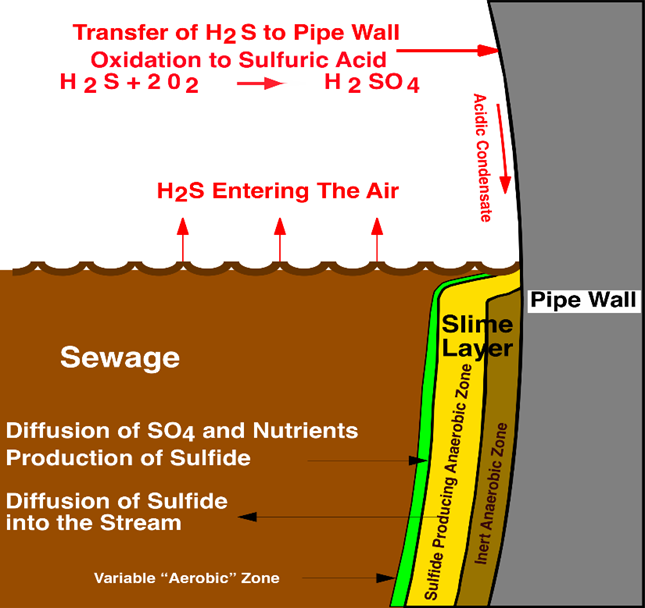

The waste we produce and flush down our toilets or drain down our sinks is full of both organic and inorganic matter. As this matter leaves our homes, restaurants, and offices, it makes its way through pipes underground and starts interacting with other components like a little waste party. Naturally occurring bacteria in the wastewater use this matter as a food source and create a “slime layer” on the surface of the sewer pipe walls. One common compound found in wastewater is sulfate (SO4). Sulfate and other nutrients present in sewage start to diffuse into the slime layer and are used by sulfate reducing bacteria as part of their metabolic process. These bacteria convert the sulfate into sulfide (S2). Turbulence in the wastewater flow causes sulfide to be released into the atmosphere as hydrogen sulfide gas (H2S). H2S gas is the most common odor compound we smell from sewers. Once hydrogen sulfide gas is released to the vapor phase within enclosed spaces, it can be oxidized into sulfuric acid on moist surfaces by a naturally occurring bacteria called Thiobacillus Bacteria. The sulfuric acid then results in corrosion of metallic and concrete materials of construction within sewers, pump stations, and treatment processes. As you can see, this biological process that produces H2S gas, causing public odor complaints and potential safety hazards, can also result in corrosion of wastewater collection and treatment systems and shortened infrastructure life cycles.

How is an odor defined and measured?

To effectively assess an odor problem, we need to identify all the odorous compounds that can be emitted from the wastewater environment. Besides H2S, wastewater also consists of other reduced sulfur compounds and volatile organic compounds (VOCs) that are difficult and costly to measure individually. In some cases, these mixtures of odors can be quantified together as a whole based on our sensory perception of the odorous compounds. Odors are often quantified by four objective parameters and one subjective parameter that describe the human olfactory response:

- Odor Concentration – What is the relative threshold of perception?

- Odor Intensity - How strong is it?

- Odor Persistency - How does odor perception change?

- Odor Characterization - What does it smell like?

- Hedonic Tone - How pleasant or unpleasant is it?

Odor concentration is the most quantifiable means of describing odorous air samples. We quantify it by determining how many times the odorous air must be diluted to reach the threshold for an olfactory response by a normal distribution of the general population. The stronger the odor, the more dilution is needed to bring the odor to the threshold of perception, and thus the higher the reported threshold value. The odor Detection Threshold (DT) is a dilution ratio that is an estimate of the number of dilutions needed to make the odor just detectable by 50% of the population. The odor threshold is reported as a dimensionless dilution ratio called the Dilution-to-Threshold (D/T) ratio, or as Odor Units (OU). The following table provides examples of ambient odor concentrations at various conditions.

The odor concentration is determined by a group of odor assessors (an odor panel) observing diluted samples of the odorous air sample using an olfactometer. During an odor test, the lucky assessor sniffs successively less dilute samples of the odorous air (each subsequent sample is presented at a higher odor concentration) until they declare a “detection” (the sample has an odor) and “recognition” (the sample has a characteristic odor) threshold. Since accurately determining the odor concentration can be relatively difficult, a common method for characterizing odors subjectively is referred to as:

“FIDO”: Frequency, Intensity, Duration, and Offensiveness.

While it comes last in the acronym, Offensiveness (which refers to the character and pleasantness of the odor) is often the most important parameter. The smell of rotten eggs vs. fresh baked cookies elicits a much different response. Intensity is more synonymous with concentration in this context, referring to the relative strength of the odor (i.e., strong vs. faint). The stronger the odor, the more likely it is to be a nuisance. The time component (Frequency and Duration) of an odor event is critical as the more frequent and longer an odor is perceived, the more likely the odor is to become a nuisance (even if the character of the odor is not offensive or is relatively faint). By accurately recording this information as part of an odor complaint log, it is possible to evaluate and develop solutions that mitigate one or more of these parameters and reduce the risk of odor complaints.

What is the appropriate response?

If you experience the smell of hydrogen sulfide in or near wastewater facilities, let it be an indicator to you that it’s worth investigating to ensure you are being a good neighbor, providing a safe work environment, and not experiencing accelerated infrastructure corrosion. The sooner odor issues are addressed, the more cost-effective and impactful the solutions can be. Our team enjoys investigating foul odors, analyzing the problem, and providing proactive solutions. We are standing by to give your facility a thorough review and explain appropriate levels of response to meet your specific situation.