Mechanisms of Corrosion in Reinforced Concrete Structures at Wastewater Treatment Plants (WWTP)

Reinforced concrete is one of the most common construction materials, especially in the wastewater industry. Concrete, in its most basic form, is a mixture of water, aggregates, cement and reinforcing steel. Concrete is strong in compression and very weak in tension which is the reason reinforcing steel is added to form a composite structure.

While concrete used in wastewater applications can be quite resilient, proper design and corrosion protection are necessary to ensure the structure lasts through its intended service life. Unfortunately, deterioration can also occur at alarming rates in the right conditions. The four common types of concrete corrosion found at wastewater treatment plants are described in the following sections.

Carbonation

Carbonation occurs almost immediately after concrete is poured as the surface of fresh concrete reacts with carbon dioxide from the air to form calcium carbonate. This reaction reduces the pH of fresh concrete, which is typically at a pH of 12 to 13. The highly alkaline environment provides passivation against corrosion for embedded reinforcing steel. Embedded steel is typically protected from corrosion at a pH of 10 or greater. Carbonation is generally a slow process dependent on the permeability of the concrete. However, if carbonation reduces the pH of the concrete to 8.5 at the depth of the reinforcing steel, corrosion of the reinforcing steel can occur.

Wide-spread damage due to Carbonation

Biogenic Corrosion

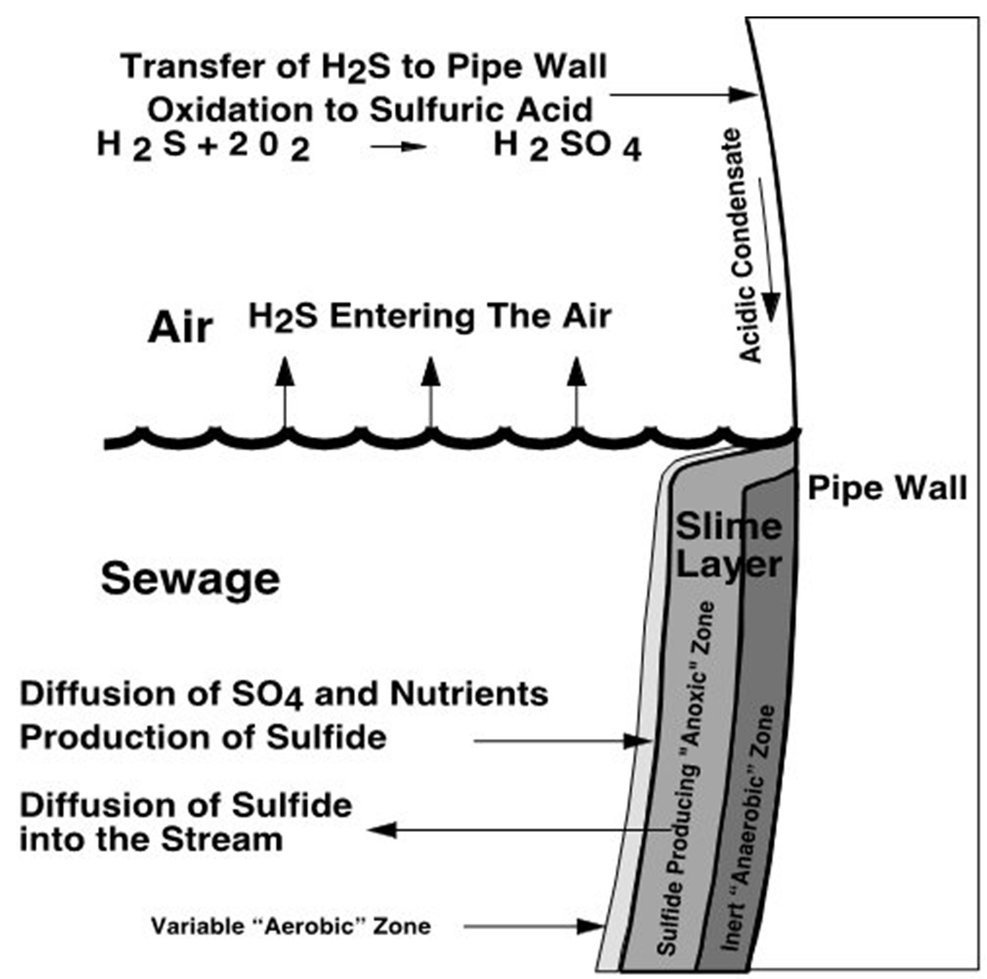

Biogenic corrosion is the process of bacterial formation of hydrogen sulfide gas and subsequent conversion to sulfuric acid. Sulfide-producing bacteria reside in the slime layer below the water line. The sulfides produced by the bacteria are dissolved into the water, then released into the air as hydrogen sulfide gas. The hydrogen sulfide gas oxidizes to sulfuric acid in the presence of moisture on the surface of the pipe. The sulfuric acid attacks the cement binder holding the concrete together, which can lead to devastating damage.

EPA research shows that biogenic corrosion rates can range from 0.1 inch to ½ inch per year. The initial rate of biogenic corrosion is likely much greater since the soft corroded material that remains on the surface provides a temporary buffer against further corrosion. Eventually, however, the soft material will slough off and expose fresh concrete to corrosion.

In V&A’s 40-plus-year history of performing condition assessment evaluations, one of the most extreme cases of biogenic corrosion was witnessed in a 96-inch reinforced concrete pipe that conveyed primary effluent. In this case, the entire section of concrete at the crown had corroded away. The severe damage was most likely caused by a prolonged or trapped air pocket that contributed to the localized deterioration of the 8-inch-thick pipe wall along the crown of the pipe. At the time of V&A’s condition assessment, the pipe had been in service for approximately 60 years.

Chloride Attack

Chloride attack typically occurs in areas where disinfection chemicals are stored or in marine environments, including the many wastewater treatment plants located in coastal areas. In these environments, chloride migration can cause corrosion of the reinforcing steel at concentrations of 250 ppm or greater. As the chlorides break down the passivation layer on the reinforcing steel, the bar corrodes, causing subsequent cracking and spalling.

The photo on the right demonstrates the effects of chloride at a coastal wastewater treatment plant. The louvres at the top of the photo are the intake to an air handling unit located inside the building. Condensation from the air handling unit, which is laced with chlorides from the marine air, caused severe corrosion of the reinforcing steel in the wall below the louvres. In this specific case, there was no evidence of spalling on the wall’s exterior, and the issue was identified from corrosion staining on the concrete floor slab around the air handling unit.

Process of biogenic corrosion

96-inch RCP primary effluent pipe with severe biogenic corrosion along the crown

Chloride attack on concrete masonry wall at coastal WWTP

Erosion

Erosion is the least severe of the four corrosion mechanisms. Erosion typically occurs at the beginning of the treatment process, where grit, debris, and solids remain prevalent in the wastewater stream. The grit and solids can literally erode away cement and aggregate.

Generally, this is not a severe issue since it typically occurs on non-structural concrete, such as concrete fill used to slope floors and sludge hoppers. However, erosion can be an issue when it reduces the concrete cover over reinforcing steel on structural members.

Corrosion Type Location along WWTP Process Train

The following matrix identifies where each type of corrosion typically occurs along a wastewater treatment plant process train.

While the damaging effects of corrosion at a wastewater treatment plant can be detrimental, proper design and the use of linings or coatings can serve as the first line of defense. Regular intervals of treatment plant condition assessment are critical to evaluating treatment facility assets to identify and counteract deterioration before it becomes a costly and devastating problem. Stay tuned for a follow-up blog post describing condition assessment methods used to identify and locate areas of concrete degradation. And as always, if you have a question and want to talk to one of V&A’s technical experts, please contact us using the link below.